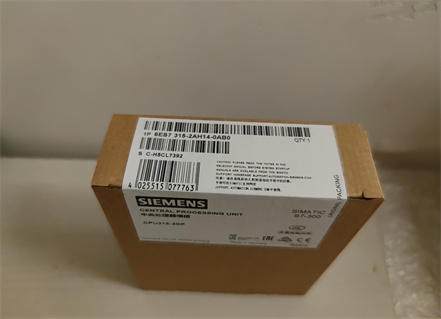

Technical rationale for the CPU 315-2 DP (6ES7 315-2AH14-0AB0) – based on reliability, PROFIBUS integration and installation safety

I. Why this particular CPU--6ES73152AH140AB0?

This decision is typically a comprehensive assessment based on historical precedent, proven maturity, economic viability and specific requirements:

1. System continuity and maturity: This CPU is a classic model within Siemens' S7-300 series, boasting a long history of release and application. Many chiller manufacturers possess standardised control libraries (function blocks, logic) developed on this platform that have been thoroughly tested. Continuing its use ensures system stability while reducing the risks and costs associated with redevelopment and testing.

2. Sufficient performance to meet requirements: Chiller control logic (such as compressor start/stop, pump control, temperature/pressure PID regulation, safety interlocks, communication management, etc.) is relatively fixed, placing non-extreme demands on CPU processing speed and memory. Its 128 KB working memory is ample for complex chiller control programmes.

3. Robust PROFIBUS-DP integration: The model designation ‘-2 DP’ indicates integrated PROFIBUS-DP master station interfaces. Chillers typically require connections to distributed I/O stations (for local sensors/actuators), variable frequency drives (driving compressors and pumps), and potentially higher-level monitoring systems (such as touchscreens or Building Management Systems, BMS). PROFIBUS-DP, a long-established and reliable fieldbus standard in industrial applications, is ideally suited for this architecture.

4. Cost and supply chain considerations: As a classic model, its procurement cost may be lower than newer variants, and spare parts are generally more readily available on the aftermarket. Once a design is finalised, manufacturers typically maintain stable hardware configurations to control overall costs.

II. Advantages of Using 6ES7315-2AH14-0AB0

1. Exceptional reliability: Industrial-grade design ensures long-term stable operation in harsh industrial environments, including vibration and electromagnetic interference.

2. Robust communication capabilities: The integrated PROFIBUS-DP interface is pivotal for efficient, reliable communication both within the unit and with external systems.

3. Familiar programming and maintenance: Engineers are well-acquainted with STEP 7 Classic software and the S7-300 series, facilitating programming, debugging, and fault diagnosis.

4. Hardware modularity: The S7-300's modular architecture permits flexible configuration tailored to specific unit functions (e.g., DI/DO, AI/AO point counts), offering excellent value for money.

III. Safety Considerations for Installation and Maintenance

Core Principle: Safety first, adhere to standards, perform operations with power disconnected, and verify accuracy.

A. Electrical Safety

1. Power Disconnection: Before installing, removing, or wiring the CPU or any associated modules, the main power supply must be disconnected and the ‘lockout/tagout’ procedure implemented to prevent accidental energisation.

2. Equipotential Bonding: Ensure the protective earth (PE) terminals of the CPU and all mounting racks/modules are securely connected to the system's earth busbar to safeguard personnel and suppress interference.

3. Power Isolation: Ensure the input terminals of power supply modules feeding the PLC system are appropriately isolated from power sources (e.g., those driving compressors or pumps) or supplied via transformers.

4. Cable Separation: Communication cables (e.g., PROFIBUS DP cables) must be routed separately from power cables. Where crossing is unavoidable, they should cross at right angles to minimise electromagnetic interference.

B. Installation and Hardware Safety

1. Correct Installation: Securely mount the CPU module onto a standard S7-300 rail, ensuring the backplane bus connector is fully engaged with adjacent modules.

2. Anti-static Measures: Before touching modules, touch a grounded metal object to discharge static electricity from the body, preventing damage to electronic components.

3. Environmental Conditions: Ensure the installation environment meets requirements (temperature, humidity, absence of corrosive gases, minimal dust). Particular attention must be paid to potential humidity issues in chiller plant rooms; ensure electrical cabinets are well-sealed and adequately ventilated.

4. Front Connector Wiring: Employ dedicated front connectors and meticulously verify wire numbers against terminal numbers per schematics to ensure correct and secure connections for power and signal lines. Use appropriate crimping tools to prevent loose contacts or short circuits.

C. Power-Up and Commissioning Safety

1. Pre-Power-Up Inspection: Prior to restoring power supply, at least two personnel must cross-check all wiring, module positions, and power voltage ratings.

2. Stepwise Power-Up: Apply control power first. Observe the status of indicator lights on the CPU and all modules (e.g., SF, RUN, BUSF). Only after confirming no abnormalities should external actuator power be gradually connected.

3. Programme Safety:

Back up data first: When replacing the CPU, fully upload and back up the programme, hardware configuration, and all authorisations from the original device.

Verify firmware version: The new CPU's firmware version must be compatible with the hardware configuration version in the programming software.

Post-download verification: After downloading the programme, test all input/output points, control logic, and communication functions step-by-step in manual mode or under conditions ensuring actuator safety.

D. Operational Maintenance Safety

1. Risks of Online Modifications: Avoid modifying programmes online during production wherever possible. If unavoidable, implement comprehensive contingency plans and obtain authorisation.

2. Battery Replacement: This CPU relies on a battery to maintain RAM data and clock settings. Replace the battery whilst the system is powered to prevent data loss.

3. Communication Network: Ensure correct connection of terminating resistors at both ends of the PROFIBUS network (switch set to ON). Network connectors and cable shielding must be reliably earthed to guarantee stable communication.

Numerous SH Automation clients have selected this Siemens 6ES73152AH140AB0 model, reporting excellent performance, durability, and safety. We welcome enquiries regarding procurement from our company.

Address: WING INDUSTRY BLDG 3, TSUN WEN ROAD, TUEN MUN NT, HONG KONG

Address: WING INDUSTRY BLDG 3, TSUN WEN ROAD, TUEN MUN NT, HONG KONG

Tel: +86 19116398948

Tel: +86 19116398948

Email: sh_plc@163.com

Email: sh_plc@163.com

Contact: Vivi Wong

Contact: Vivi Wong